As the demand for eggs continues to grow, poultry farms face increasing pressure to enhance efficiency and ensure the highest quality standards. During peak production periods, manual egg collection can be time-consuming and labor-intensive, often leading to higher breakage rates and compromised hygiene. This is where automated egg collectors step in, revolutionizing egg collection with streamlined processes and consistent results.

This guide explores how automated egg collectors work, their key benefits, and how they can transform your poultry operation.

How Automated Egg Collectors Work

Automated egg collectors are designed to handle every stage of the egg collection process, ensuring speed, precision, and hygiene.

1. Efficient Egg Collection

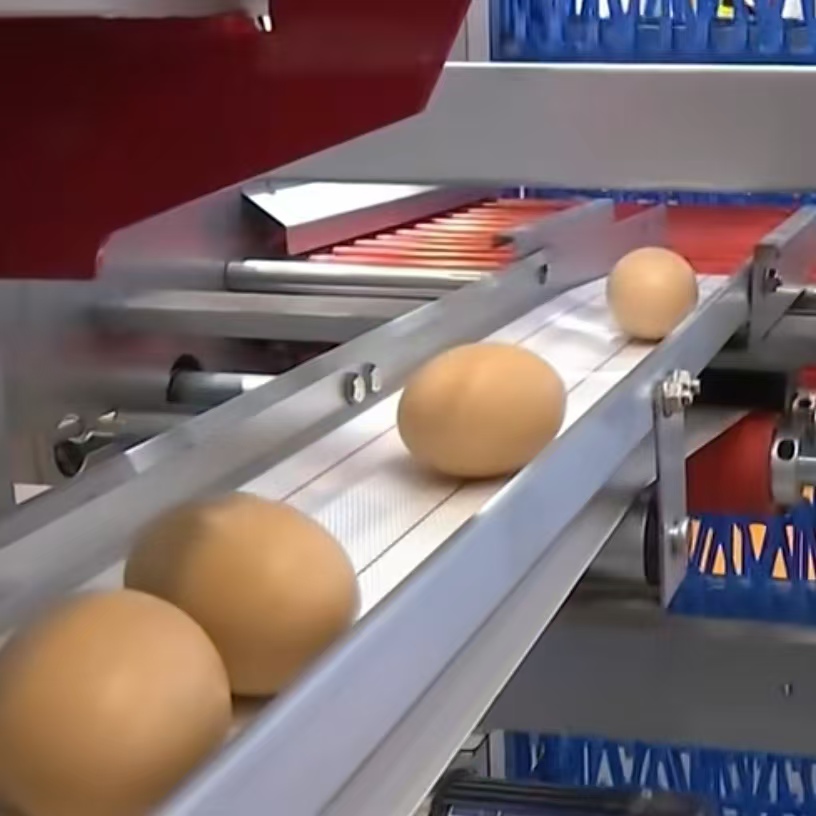

Eggs are swiftly gathered from designated collection trays or conveyors, reducing the time eggs remain exposed in the laying area. This minimizes contamination risks and ensures eggs are collected in optimal condition.

2. Automatic Sorting System

Once collected, eggs are transported through a sorting system. Here, they are classified based on size, color, and quality. Advanced sensors ensure that sorting is both accurate and efficient, helping farms meet market standards with ease.

3. Comprehensive Cleaning and Sanitization

Collected eggs pass through a cleaning and sanitization unit, where dirt and bacteria are removed. This ensures compliance with food safety regulations, giving consumers peace of mind.

4. Coding and Packaging

Eggs are stamped with essential identification codes, such as production date and batch number, before being packed into cartons or trays. This final step prepares eggs for immediate transport or storage, facilitating streamlined logistics.

Unmatched Performance During Peak Production Times

Automated egg collectors excel during peak production, where the sheer volume of eggs can overwhelm manual collection systems. With processing rates reaching 50,000 to 60,000 eggs per hour, these machines are indispensable for scaling up operations without compromising quality.

Key Advantages of Automated Egg Collectors

1. Reduced Labor Dependency

Manual egg collection often requires large teams working long hours, especially during peak seasons. Automated egg collectors minimize the need for labor, allowing staff to focus on other critical aspects of farm management.

2. Improved Egg Quality

By streamlining cleaning, sorting, and packing, automated systems ensure eggs are handled with care and meet stringent quality standards. The result is a consistent supply of high-quality eggs that consumers trust.

3. Minimized Losses

Breakage and damage are common issues in manual egg handling. Automated systems reduce these risks through precise and gentle handling, lowering overall losses and boosting profitability.

4. Enhanced Hygiene

The automated cleaning and sanitization process reduces the risk of contamination, ensuring eggs are safe for consumption. This is especially crucial for meeting regulatory requirements in global markets.

Choosing the Right Automated Egg Collector

When selecting an automated egg collector, consider the following factors:

- Capacity: Ensure the machine can handle the peak production volume of your farm.

- Durability: Look for machines built with robust materials to withstand daily use.

- Automation Features: Opt for systems with advanced sorting, cleaning, and coding functionalities for maximum efficiency.

- Ease of Maintenance: Select models that are easy to clean and service, ensuring minimal downtime.

- Energy Efficiency: Machines with energy-saving features can reduce operational costs in the long run.

Optimizing Your Poultry Farm with Automation

To maximize the benefits of automated egg collectors, integrate them into a well-planned farm workflow:

- Train Your Team: Ensure staff are trained to operate and maintain the machinery effectively.

- Regular Maintenance: Schedule routine inspections to keep the machines running smoothly.

- Monitor Performance: Use data from automated systems to identify bottlenecks and areas for improvement.

- Combine with Other Automated Systems: Pair your egg collector with automated feeding, watering, and ventilation systems for a fully integrated operation.

Why Automated Egg Collectors Are the Future of Poultry Farming

As poultry farms scale up to meet global demand, automation will play a critical role in ensuring efficiency, sustainability, and profitability. Automated egg collectors not only streamline daily operations but also enhance product quality and safety, giving farms a competitive edge in the marketplace.

By investing in the right technology and implementing it effectively, you can elevate your poultry business to new heights.

Conclusion

Automated egg collectors are an essential tool for modern poultry farming, especially during peak production periods. Their ability to handle large volumes efficiently while maintaining high hygiene standards makes them a valuable asset for any operation. By reducing labor dependency, minimizing losses, and ensuring top-notch egg quality, these machines pave the way for scalable and sustainable growth in the poultry industry.

Ready to upgrade your poultry farm? Explore the latest automated egg collectors today and revolutionize your egg production process!